When forced to ‘tell us something about yourself’ in meetings or social situations, I would respond with something like

“I’m a physicist by education, a machinist by trade, I’ve made a living doing IT for the last few decades, and when I grow up, I want to be a welder.”

Maybe it’s time I grew up?

I want something. If I were smart I’d buy something that’s already built. Or I’d have professionals build it for me. If I were not, I’d build it myself. I’m building it myself, so apparently I’m not.

Actually – what happened was that I put money down on a product, the company failed to deliver the product & stopped communicating. Of course after I had Amex do an $8000 chargeback, they clamed that my build was a couple weeks away.

No thanks.

A good build has to start our with a project plan. My project plan has three milestones:

- Buy Welder

- Learn How to Weld

- Build Camper

Simple, right? 🤣

The camper will be built from aluminum tubing, so the first two steps have to be aluminum-capable. That means a new AC/DC TIG welder (Lincoln Square Wave 205) and lots of practice. Welding aluminum is strange – the oxide layer doesn’t melt and the amount of heat needed to get the aluminum soft and mushy enough to weld is really close the amount of heat needed to drip liquid aluminum down into open-toed sandals – something which only those who weld in open-toed sandals would know, of course.😏

Learning to weld (for me) means lots of YouTube videos, lots of practice, and lots of bottles of expensive welding gas (Argon). I watched enough YouTube to have earned an official ‘YouTube Certified Welder’ sticker and the local welding supplier greets me with an “Again?” comment.

Practice pays. With enough practice, I can reliably determine if a weld is good or bad. Mostly because I have a library full of samples with bad welds to reference. But I figure I’m good enough that if I back up my welds with rivets, exotic 3M adhesives and Gorilla Tape, I should be able to move on to step three.

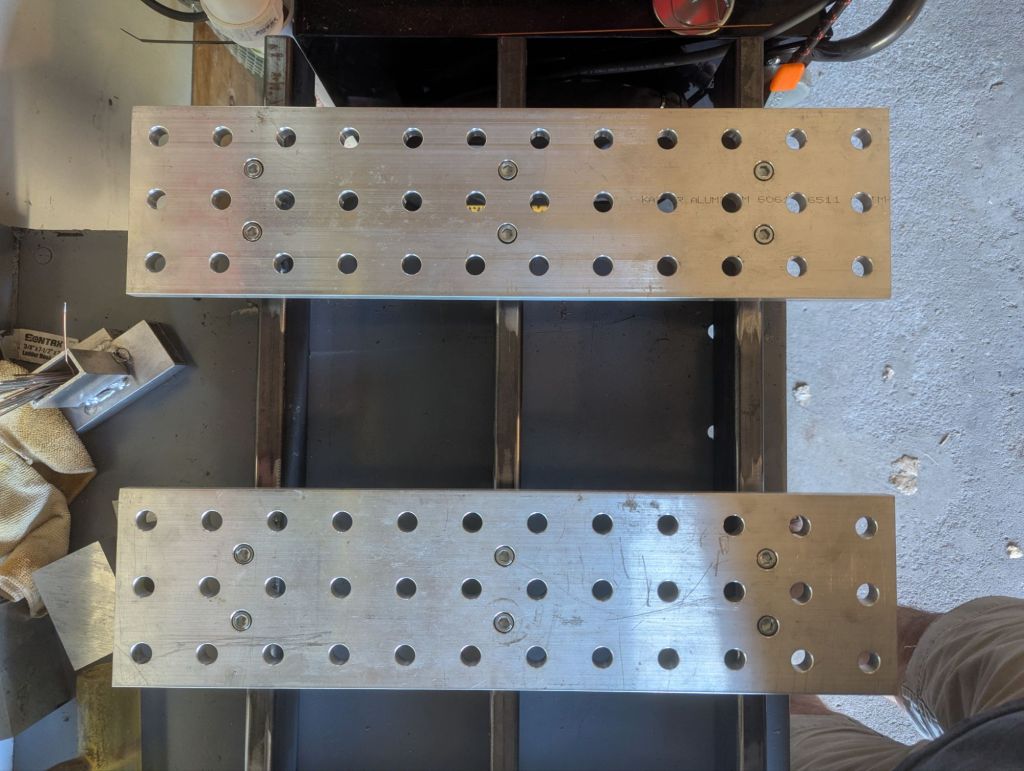

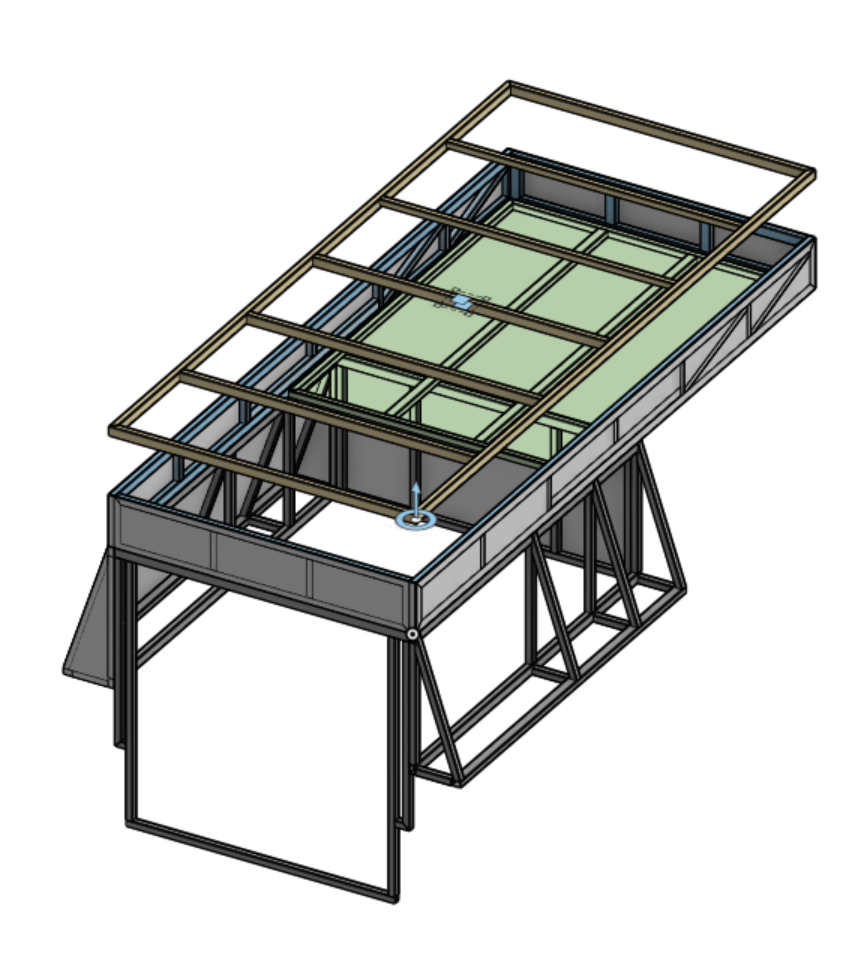

But first I need something to clamp stuff to when welding. Some people buy or build a welding table or a fixture table, others use their garage floor. Garage floors suck, so I built a fixture table that sits on one of my benches. It consists of 1″ x 3″ x .125″ steel tubing with tapped riser blocks welded on top, and six 6″ x 24″ x 5/8″ aluminum plates, CNC drilled and reamed with .625″ holes spaced 2″ on center. The plates are bolted to the steel tube frame. I left 6″ gaps between the plates, partially because I want gaps for positioning clamps – mostly because the plates cost a hundred bucks a piece and half as many plates cost half as much.

When I TIG welded the riser blocks to the tube frame, the frame warped. Apparently welding is synonymous for warping. Fortunately YouTube hosts plenty of videos on how to straighten warped weldments using a oxy-acetylene torch, magic incantations and a bit of luck.

As it sits right now, the frame and plates are flat to within .010″ across their 5′ 6″ length and 2′ width, the holes in each plate are positioned within +/-.001″ & sized to .625″ plus a half thousandth minus zero. I used one plate set longitudinally and a handful of .001″ undersized dowel pins to space out the plates longitudinally, so even after welding warping the plate spacing is good to within .005″ or less.

Good enough for welding warping a camper.

While step one & two were in progress, I starting to draw out something resembling a camper. Of course that meant getting sidetracked into learning 3D parametric modeling. Unfortunately the half-assed AutoCAD skill set that I had fully polished as recently as 35 years ago wasn’t much help. 21st century parametric modeling is backwards and upside-down from drawing lines and dimensions in circa 1990 AutoCAD.

My plan is to have a camper shell with an aluminum tube frame semi-permanently fastened to the truck bed; aluminum or composite skin panels; and a popup top made of folding aluminum side panels and an aluminum top. If that is too messy to build, the pop-top will have simple canvass sides and an aluminum top. Sleeping area will be partially above the cab – the only way I can get a long enough sleep platform in a 5′ truck bed.

If this works out, at some point in the future I’ll have something resembling a camper sitting on my truck. Or I’ll have a welder, fixture table, and half a garage full of scrap aluminum.

At this point it’s had to predict the future.

Leave a reply to clara87b5b84d09 Cancel reply